It may be useful to print this out for cross reference when following the guide:

Daddy, where do baby pedals come from?

Start off with this bad boy here. Vero board slab bought from Tayda Electronics.

Once you know what pedal you wanna build you find/make a layout blablahblah. I'm making a Menatone Red Snapper with IvIark's layout.

I cut it down to size and file the edges (cosmetic reasons..)

I then mark out for the trace cuts and drill a hole to start the cut.

I then grab a bigger drill bit and cut the traces by hand.

Then i add the jumpers in.

And boom, we have a board ready for components!

Okay so now that we have the board ready, i add components.

I start with resistors cause they are the shortest in height. I use RN55's cause they are killer.

Then diodes. Used 1n4001's cause i love em.

I then use an IC. This is an old school JRC4558.

Then come the caps. I use Phillips ones for pedals like this for size reasons. Theres also a Silver Mica in there.

Then polarised caps. I LOVE KEMET ONES (the one that looks like a bullet) CAUSE THEY LOOK SIIIICK!

And there we have a populated board!

Now to wire it into an enclosure..

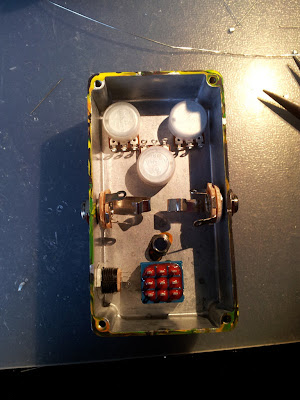

Here's one i prepared earlier!

Fill it with the required parts.

Now for wiring. I start normally with the LED and grounding.

Then input and output jacks.

Then more power/switch wiring..

Looks kinda messy at this stage. but dont panic! I then add the circuit in last!

All done!

Works a treat first time

super clean.

ReplyDeleteWhat's the plastic things on the pot? It can be my solution of isolation since 3 years!!!

ReplyDeletePot condoms! They come with pots bought from Tayda.

Deletehttp://www.mammothelectronics.com/mobile/default.aspx#P1557

DeletePot Condoms! I'v never heard them called that, but i do love it. Stealing it for all future use.

Delete

DeleteIt's been called that for a while now... :)

http://www.guitarpcb.com/apps/webstore/products/show/1409402

So what is the purpose of drilling the extra large holes? Is it for ventilation?

Deletethe larger holes are the cuts in the board and the copper tracks below.

DeleteThese are alpha pots and the come with the pot cover... They are also $4.39 for 5 pots and that is about 88 cents per pot.. Minimum order of $10.00 and free shipping on all orders

ReplyDeletehttp://www.thaishine.com/servlet/the-Potentiometer%E2%80%8Bs-cln-Rotary-Potentiomete%E2%80%8Brs/Categories

OK, so I'm curious. Why does it appear that Timmy used 3 different types of 10K resistors on this board?

ReplyDeleteNo idea unless he only had a few of each. It is quite cool having 3 different Dale metal film resistors in the same build at the same value though! :o)

DeleteCan somebody please tell me if 4u7 means 47 uf or 4.7 uf

ReplyDeleteThanks

4.7u. The letter always takes the place of the decimal point, such as 2K2(2.2K), 4M7(4.7M), 6N8 (6.8nF) etc

Deletesooo... using that switch wiring configuration, do you have any trouble with switch pops? i now there are millions of answers on forums for this but i've tried everything and i was wondering... do you have any suggestions?

ReplyDeletethis problem is really putting me off building .. thanks!

No way of wiring the switch will necessarily prevent popping which is normally a result of the actual circuit or the LED. The true bypass method Timmy used here seems to be the conventional true bypass wiring, like this:

Deletehttp://www.little-black-box.co.uk/images/uploads/wiring-diagrams/3pdt-wiring.jpg

Except Timmy used the middle pole for the LED rather than the right hand pole shown in that diagram. I use the method shown in the Offboard Wiring page which grounds the input during bypass which can stop noise bleedthrough that you get with some higher gain circuits.

If you want to silence popping you will need to add a pulldown resistor between the input wire (PCB side not socket side) and ground which helps in most cases. If you're still getting popping check out Jack's write up on LED popping here:

http://www.muzique.com/lab/led.htm

Hey,

ReplyDeleteQuick question - what do you support the circuit board on? I can't see any screws so I'm guessing it's just floating with some foam or something on the back to stop it shorting on the pots etc.?

Great site by the way!

J

I don't think timmy used anything with this because those solid core wires keep everything firmly in place, but I always use sticky backed velcro. A couple of small squares on that back of the pots and a strip stuck to the back of the vero.

DeleteGreat idea!

DeleteOk, cool. Thanks.

ReplyDeleteWhat wire would you recommend for Builds Mark? I've been using 22awg stranded and then tinning. A lot of other friends are suggesting 24awg pre-bonded - would this fit through the vero board holes? Can you suggest a UK supplier? Cheers

ReplyDeleteA potentially useful tool: a razor (also known as hobby) saw. I'm getting tired of the X-acto knife for cutting vero, and this is probably next on my list.

ReplyDeleteWhere does the battery fit into this enclosure?

ReplyDeleteIf you want a battery you'll have to space it out appropriately. I've never made a pedal for myself and included a battery snap because a daisy chained power supply is so much more convenient to me, giving one less thing to think about. If there was ever a problem with the power that would stop my daisy chain working, then my amp wouldn't be working either.

DeleteI'm just about to box a Craig Anderton Freq Booster and wondered how I might get all the parts in including a battery after looking at this! Damn it I'll cram it!!

DeleteMount the vero upside down and you'll get it in easily

DeleteThis comment has been removed by the author.

ReplyDeleteAnybody know where to buy that cloth covered wire? I remember seeing it in old Fender amps, and it seems really easy to work with!!

ReplyDeleteAlso, is that just a diode to ground (fom 3PDT), to prevent shorting it? Schottky? Never done that myself, but i believe I just blew a mosfet (on a millenium circuit), because the wire from my power supply touched the unfinished, grounded enclosure...

Are there any steps in preparing the veroboard? I'm going to start building a Timmy clone, but i've read in some forums how people needed to sand, i think, the copper in order to get better contacts. Is this suggested or completely unnecessary? My board is from Tayda

ReplyDeleteOthers may have different recommendations but I've never prepared a vero in my life and I've never had any problems. Anything that adds an extra step and unnecessary extra time to a build is a big no no for me.

DeleteFor the Timmy build I've seen them built with a stereo input. Does it matter what we use? I have both mono and stereo jacks but wanted to make it as similar to the original

DeleteI bought these boards from Tayda:

ReplyDeletehttp://www.taydaelectronics.com/prototyping-board-120x80mm.html

I realized that the backside didn't look the same as the strip boards that I see on here. These just have circular copper pads instead of the copper strips all the way across. Are these just for prototyping and will not work inside of a pedal? Should I just go ahead and get some of these instead:

http://www.taydaelectronics.com/small-stripboard-94x53mm-copper.html

Thanks so much in advance

-K

Those are called perfboards. And they are used in very different manner than the stripboard - So you basically can't use those with these layouts. Check Runoffgroove.com for some perf layouts...

Delete+m

Hi there. The veroboard layouts seem easy enough to handle, but I'm having a trouble wrapping my head around the wiring for the external components like pots, power supply, input etc. The layouts dont seem to address it, as far as what pins on pots, connecting to output, etc. I'm a pretty rank beginner, so I was hoping to find some info on pedal builds but this only looks to get me half way. Can you offer some advice on how to figure that out?

ReplyDeleteHi, check out the off board wiring guide in the off board tab at the top of the page.

DeleteHey, what are you using for jumpers? I'm just starting to use your diagrams to build (which are FANTASTIC!) But i don't know what you use as jumpers!

ReplyDeleteUse cut off leads from resistors and caps, or zero ohm resistors if you really want to.

DeleteThanks :)

DeleteYup, i used cut off leads from resistors and diodes.

ReplyDeletelvlark Do you know where to find the cloth hook up wire? I'm new to this and I've bought almost all of the parts from Tayda and Mammoth Electronics but they don't have the cloth hook up. Also I search for it but the come in different Ga and volt rating. I was thinking of going 20Ga. Stranded 600v tolerance. Is that good? or should I go for another gauge? Thanks!

ReplyDeleteCould you add a picture to this that shows the soldering joints on the underside, I would like to see what is happening down there (I am a newb).

ReplyDeleteAlso, when I see the red squares in the layout I am assuming they are there to break the connection within the rows on the veroboard?

Deleteyes the red squares is where you would use a drill bit to break the copper connection

Deletenot mine but

Deletelink to solder side of a strip board

http://makezineblog.files.wordpress.com/2011/12/weekendprojects_stripboard-arrows3big.jpg?w=614&h=461

that is great. thanks!

DeleteWhat kind of capacitor is 100pF one? A ceramic disk? Can i use any non polarized cap for this? Thanks

ReplyDeleteAre you not supposed to ground the enclosure to make a faraday cage? I haven't seen any discussion about that on here or beavis audio or any other resources.

ReplyDeleteBasically yes.

DeleteBut.

The open framed jacks used in this tutorial connect the jack sleeves (which are grounded) to the box on both sides.

If one uses shielded jacks (like in original EHX V8 Black Russian, for example), then it is imperative to ground the box too.

+m

Hey

ReplyDeleteAm I right in thinking Tim has wired the cathode to the sleeve of the input jack with the ground to the power and then has the current limiting resistor normally attached to the anode of the LED running from the +ve of the power jack through pole 5 and 6 of the switch?

He also seems to have the board and all other grounds going to the sleeve of the output jack. I'm assuming these all ground themselves when the pedal is plugged in because I can't see how they get back to the -ve on the power jack otherwise from the pics?

:)

I have just but one question about this. Where does the output line go? I looked at all the boards in all of the blogpost but I've never seen them on the veroboards. Are they only attached to the volume pots or is there some output line that is connected to the board itself? Since there was no schematics shown on most of the vero layouts here. Thanks in advance!

ReplyDeleteOutputs are either taken from the board or from one of the pots. This is always clearly marked. From board/pot you go to the footswitch and from there out to the tip of the output jack.

ReplyDeleteDo you need examples?

yes please appreciate it. Like where is the output if its on the board or how does it go if its on the pot. It's this only riddle that I'm having a hard time but most of the offboard wiring and build is already done.

ReplyDeleteWith these layouts, the output of the board going back to the stomp switch is marked "Output". Or if there is an end of circuit volume control it is marked Volume 3 with instructions of where volume lugs 1 and 2 need to go in the notes of the layout.

Delete@MPB: OK here you go, I'll try to be as graphic as possible. :)

DeleteFirstly, you need to religiously follow this:

http://tagboardeffects.blogspot.com/2012/02/offboard-wiring.html

you see where the blue wire connects the board output with the footswitch, that's just a general representation. Output in this case means "whatever is specified as output on the actual build).

Output jack is always connected to the footswitch.

You can have the output on the board itself like here (blue wire marked "output" on the left side of the board)

http://tagboardeffects.blogspot.com/2012/02/little-angel-chorus-rick-holt.html

in which case you do indeed follow the offboard wiring to the

letter and connect the board to the footswitch.

On the other hand, you can have the output taken from one of the pots, like here

http://http://tagboardeffects.blogspot.com/2012/02/mid-fi-electronics-clarinot.html

There's no output marked on the board but in the notes below it states "vol1 to gnd, vol2 to output". Lug 2 of the volume pot needs to be connected to the footswitch, as described in the offboard wiring picture. In effect, lug 2 is now what you see as "output of the board/effect" and it needs to go to the footswitch.

Hope this helps. :)

Can someone please tell me how all the grounds connected to the output jack get back to 'common ground' on the DC jack? Or does it somehow ground via the enclosure. I thought it might be via the board ground but it's attached to the output jack also.

ReplyDeleteIf you do it as per Mark's diagram here,

Deletehttp://tagboardeffects.blogspot.com/2012/02/offboard-wiring.html

output jack's ground goes to footswitch and input jack ground. Input jack is then grounded to the dc jack and your board.

Thanks Goran, however I actually wire my true bypass exactly as shown in this build guide as I like to wire the CLR from the DC straight to the switch. However I normally either connect all my grounds via star grounding (pain as you end up with heaps of wires joint at one spot, not my preference) or I combine them all via a small piece or vero (works well but feels a touch clunky) Thought this build guide might show a simpler way but just cannot see how gets back to common ground. Either way I can stick to my vero option, was just hoping someone might be able to explain it for me. :)

Delete

DeleteOh, I see... you meant THIS particular build, not any build in general! I really shouldn't be writing anything before 9AM... :)

In this particular case, my guess (since I only see the dc groung being connected with one of the jacks) is that he's using the enclosure to connect the grounds. It is true that when you screw the jacks to the enclosure the enclosure itself gets grounded through the sleeve. As long as there's contact between bare metals of the jacks and the enclosure, this should work fine.

I wouldn't trust Tayda's jacks with this, though. :)))

Thanks so much Goran. Makes total sense and you 9AM replies are pretty solid for what it's worth ;)

Deletegreat to see this still getting used!

ReplyDeleteWhat wire do I buy for the jumper "cables"?

ReplyDeleteWhatever suits your fancy. I mostly go with component leads leftover from previous projects, especially for the links that need to fit underneath the IC. For longer spans I go with regular hookup wire, whatever I have at hand at the time. Basically whatever gets you from A to B without getting in the way of other components is fine.

DeleteSo it does not matter if it is stranded or coated? It always looks more like the component leads in the pictures. What gauge would you recommend?

Delete(Sorry, two accounts!)

So does it matter if it is solid core or coated? The pictures make it look more like component leads than hook-up wire. What wire gauge would you suggest?

Delete(Sorry, two accounts!)

So does it matter if it is solid core or coated? The pictures make it look more like component leads than hook-up wire. What wire gauge would you suggest?

Delete(Sorry, two accounts!)

I use 22 gauge wire (some use 24) and as a starter use stranded. It is flexible, easy to maneuver and hard to break. The ends need to be tinned (look up a youtube video on how to do this) to make it easier to work with. If this is new to you, get stranded. It's easier to access anyways from any electronic shop.

DeleteI now use solid core because I know where I want my wires to go (as does Timmy in the build guide) but it's not a great starting wire because too many bends and it snaps. It doesn't need tinning however. :)

Delete@chum: It seems that you are talking about the harness (offboard) wiring, my reference was to board jumpers.

Good info, though! I use prebonded stranded, best of both worlds IMO...

Oh dear. Thanks Goran for enlightening my tired brain. I use cutoff component leads, especially the nice chunky ones from diodes and caps... cos they make me feel better.

DeleteThis build guide is great. I am completely jealous. But I have issues. I don't understand how you solder the circuit board in last with the solder on the backside?!?! You go from "lookin kinda messy" to abracadabra the board is soldered onto 7 rigid wires from the backside. Am I crazy here? Are you removing the entire populated enclosure, then soldering the circuit in, and then putting it all back into the enclosure?

ReplyDeleteI tried this method of putting everything in the box first with my Keeley 4-knob, and I had to put a bunch of extra wire in to be able to flip the circuit over. Result, a rats nest of wire that I had to cram in the box. Mind you, I used flexible wire, not the rigid stuff.

Issue #2: A lot of people on this forum say things like, "I finished it tonight, it sounds great. I'll be boxing it up tomorrow."

Well, if you finished it, and it isn't boxed, that means you didn't do it the way this guide says. Are you going to de-solder everything and then do it this way? Or did you wire it up on the desk with a "plan" in mind to just drop it into an enclosure? THAT is how I do it, but it still never comes out as clean as you guys get 'em.

Boxing is now my most loathed part of this hobby. PLEASE HELP ME! :D

Hey Mojo 321. I'm no expert but here's my responses from what I've learnt using this guide. I leave just enough wire so I can thread it into the vero right at the end, just flip it over and solder it. Then flip it back. I use solid core wire like in this build guide so it doesn't bend far but works well for me. I found the first few times I had a 'rats nest' of wire and slowly but surely learnt the right lengths to use. Being able to make things neat and structured is done by just building and building and building. You'll get it. Please note Greeny is an expert builder who has been at it for a long time and has a great reputation.

DeleteI tend to build and box all in the same sitting, that's my thing but some people will possibly build the board and hook it up to a test kit with pots and jacks etc to make sure it works before wasting all the time wiring it into an enclosure. I tend to problem solve once it's in the enclosure but certainly don't recommend this as ideal if you don't know what you are doing. Some others might even just breadboard these circuits to see how they sound before soldering anything together at all. Just my thoughts.

There is now a great thread going in the forum under "Boxing Thread". Thanks all for sharing your tricks over there for us beginners!

ReplyDeleteHi there what function is the black (diode,cap looking thing) have and what value do you use

ReplyDeleteI'm with Andreas. I can't believe no one else has commented on it before now but there is what appears to be an RN60C Resistor connecting the foot switch to the DC jack. It looks to me like it says [something].65K on it, but there's nothing like it on the parts list.

DeleteHi Jumbled and Andreas. That is the LED resistor. He has it connected from the 9V on the DC jack through the footswitch to the anode (+ve leg) of the LED and the cathode (-ve leg) of the LED to the ground sleeve of the input jack. This way when the foot switch is engaged it connects the 9V power via the resistor to the LED and it lights up. When the switch is off the LED is off. I think it's quite a 'pretty' way of hooking it all together however after using it myself for a few months I found with standard flimsy lead resistors you often found they eventually moved and started touching things. I now mount that resistor on the vero itself even if it means adding a column. I'm now 'one of those guys'. haha

DeleteThanks for the response, Chumbox. I think that makes sense, but can you tell me what is the correct size resistor for that LED? I'm glad it came up because I need to double check to ensure that I used the correct polarity for the LED anyway.

ReplyDeleteIn the illustration, it appears that Timmy's LED Resistor lead connects through the middle bottom lug on the foot switch and then to the center lug as well. Is that correct? I will not have to be concerned with the resistor lead touching the jumper between the bottom left and right lugs because I used an insulated wire segment there. I am building the pedal in a configuration like the original Red Snapper (1590BB box with the foot switch in the bottom right edge, so that jumper would have shorted on the box otherwise.

One thing I'm going to leave right here is that, for a noob, Mark's original tagboard drawing from Feb 14, 2010 (http://tagboardeffects.blogspot.com/2010/02/menatone-red-snapper-3-knob.html) has a clearer picture of which leads connect to which lugs on the pots. The Vero layout is easier to build, but the pot connections are left to experience that some of us don't have yet.

This comment has been removed by the author.

DeleteI found a calculator to help me figure out what resistor I needed for my LED. Unfortunately, it cames back with 350 Ohms, 280 mW, 20mA. I can't find a resistor that comes near that; did I put in bad data?

DeleteHere's the LED Tayda sold me:

Diameter: 3mm

Forward voltage(V): 2.0-2.2

Current(mA): 20

If I can find what I need in town, I may be able to finish this evening, otherwise, I'll have to place another order.

I wouldn't look too deep into it. It depends greatly on the type of LED and what sort of illumination you have a preference for, and a calculator doesn't tell you that. I find with conventional LEDs that a 2.2K resistor is about perfect for me because I never want them blindingly bright. Super bright LEDs and you may prefer something in the range of 10K to 15K.

DeleteI'd suggest experimenting with a battery, a breadboard (or even a terminal block to make the connections) and a few different resistor values to see what works for you.

That's cool, Mark. I got some extra 10K resistors and the LED is labelled as Ultra Bright, so I will put one of those in there.

DeleteI'm really nervous about this build. I know I need a better soldering station and the iron is a 25W from about 1993, so the solder job has been a bit sloppy, but close inspections don't reveal any slag crossing the lines.

I used a 15 or 20W soldering iron for a few years before getting a station so there's no problem using them. As long as the tip is ok that's the main thing. My first soldering iron had a fixed chunky tip and that was just useless for me with this kind of thing. If it's pointed or with a small flat area it'll do nicely.

DeleteOK, so once again, this is my first build and I am feeling particularly lost. Maybe I'm no more so than any other noob, but I've gotten myself thoroughly confused. I may need some counseling on this one. Perhaps I am looking at too many pictures but between the Red Snapper Vero drawing, the Offboard Wiring Vero drawing and the Tagboard drawing that shows the 3 knob layout, I'm messed up.

DeleteI'd like to ask some questions, but I hesitate to load up this blog entry with them because others who aren't confused might become so. Is it better to load them up here or is there someone who might volunteer to answer some questions offline?

Ask away here like Travis said. Good community. Everyone was a noob at some point.

DeleteI suggest you just ask away right here. We're all happy to help when we know how, so it's best to get a varied response :)

ReplyDeleteThis comment has been removed by the author.

DeleteThis comment has been removed by the author.

DeleteThis comment has been removed by the author.

DeleteUPDATE: Once again because of the way my mind works, I need a picture. This time, however, I gave drawing it myself a shot.

DeleteThis link will take you to a DIYLC-generated image that I drew using the 2 available drawings for the 3-knob along with the off-board wiring schematic.

If someone could please sanity check it for me, I will feel safe wiring and firing it up!

My Understanding of it

Power-up attempt #1 was a failure. The pedal passes the signal through when off, but all I get when I activate the switch is a hum. I did run a box cutter blade through between the tracks to make sure I didn't have any solder slag jumping strips.

DeleteIf you haven't already done so, take a look at the drawing I created to try to help me understand the full logic (Link) and then the list below is every wire I have connected to what.

I really would appreciate any help you can offer. I feel like I've been a pain, but this is something I really want to learn to do. Thanks!

DC Jack 9V+ = 1 lead to circuit board (D-17)

& 1 lead to 10K Resistor for LED Anode

LED cathode = 1 lead to 3PDT switch lug #1

DC Jack tip = 1 lead to Input Jack ring

Input Jack tip = 1 lead to 3PDT switch lug #9

Input Jack ring = 1 lead to DC Jack tip

& 1 lead to circuit board ground strip (K-15)

Output Jack tip = 1 lead to 3PDT switch lug #8

Output Jack ring = 1 lead to Vol 1

& 1 lead to Bite 3

& 1 lead to circuit board ground strip (K-17)

Vol Pot lug #1 = 1 lead to Output Jack ring

lug #2 = 1 lead to 3PDT switch lug #7

lug #3 = 1 lead to circuit board (A-17)

Bite Pot lug #1 = Empty

lug #2 = 1 lead to circuit board (C-1)

lug #3 = 1 lead to Output Jack ring

Gain Pot lug #1 = 1 lead to circuit board (H-1)

lug #2 = 1 lead to circuit board (D-1)

& 1 lead to Gain lug #3

lug #3 = 1 lead to Gain lug #2

3PDT switch lug #1 = 1 lead to LED cathode

lug #2 = 1 lead to 3PDT switch lug #3

lug #3 = 1 lead to 3PDT switch lug #6

lug #4 = 1 lead to 3PDT switch lug #9

lug #5 = 1 lead to circuit board (K-1)

lug #6 = 1 lead to 3PDT switch lug #3

& 1 lead to circuit board ground strip (K-16)

lug #7 = 1 lead to Vol Pot lug #2

lug #8 = 1 lead to Output Jack tip

lug #9 = 1 lead to 3PDT switch lug #6

Circuit Board A17 = 1 lead to Vol Pot lug #3

C1 = 1 lead to Bite Pot lug #2

D1 = 1 lead to Gain Pot lug #2

D17 = 1 lead to DC Jack 9V+

H1 = 1 lead to Gain Pot lug #1

K1 = 1 lead to 3PDT switch lug #5

K15 = 1 lead to Input Jack ring

K16 = 1 lead to 3PDT switch lug #6

K17 = 1 lead to Output Jack ring

Are you sure the input and/or output jack are grounded properly? It isn't connected to the other grounds other than through the case and if either the input or output jacks don't have a good connection to ground through their physical mounting then that could cause noise. Hum often suggests a ground problem so it would certainly be where I would check first.

DeleteSorry, Mark. I reported an incorrect symptom. I realized tonight that the power supply I pulled out of my extras pile was actually positive center, not negative center. That's where all the hum came from.

ReplyDeleteNow that have I connected the correct power supply, I have a clean signal in bypass mode, but when I activate the switch, I get a quiet hissing sound, but absolutely no guitar sound (strumming makes no discernible change). The LED does come on when the switch is active. Any clues?

You need to give us a bit more info. Measure the DC voltage between all IC pins and ground. That's usually the easiest way to spot an area which is misbehaving.

DeleteMark,

ReplyDeleteUsing the traditional numbering for IC pins:

1 - 6.59

2 - 6.59

3 - 3.3

4 - 0

5 - 6.5

6 - 6.53

7 - 6.49

8 - 13.1

Thanks!

How are you getting 13.1V out of a 9V power supply?

DeleteJust double checked the power supply. It states "9.0 VDC, 300mA" and it's the one I have been powering my 5 existing pedals with, so I trust it.

DeleteCould one of the capacitors be acting as a charge pump and storing up greater than 9VDC in the circuit? I guess if anyone else would be willing to check the voltage on their own pedal, we could compare them.

A cap cannot do that.

DeleteMeasure the dc voltage between the tip and sleeve of the power supply. I've seen regulated power supplies that give out a lot higher voltage than they should. The cause has always been the burned regulator inside the supply. If you've used that supply for testing your boards, then it's more than likely that you've shorted the supply out at some point.

I strongly recommend testing all the boards with a battery. You can solder the 2.1x5.2mm plug tip straight on to a battery snap and use that. A battery is a lot cheaper to burn than a AC/DC supply when testing.

I've burned a few of supplies myself...

+m

Thanks Mirosol ...... had a noise problem with picoso boost and just connected the battery and it works thanks mate !

ReplyDeleteHello everyone! I just wanted to share a tip that I'm using when it comes to mark out for the trace cuts, adding jumpers even the components, especially in larger veroboards. I first number the layout (both rows & columns)

ReplyDeletehttps://drive.google.com/file/d/0B7DoTp4ra27rRHJZV0lHVzFGYjA/edit?usp=sharing

Then I stick some tape on the sides of the veroboard and do the same.

https://drive.google.com/file/d/0B7DoTp4ra27rME02UXc4NFcxNkk/edit?usp=sharing

It really helps me getting to the right holes easily, without counting again and again just to triple check that I'm right.

Thanks for sharing

DeleteHi,

ReplyDeleteI`m about to complete the Zendrive...How do you fix the board in place after you`ve made all the solders?

And what is the best way to cut the vero to size without breaking it?

Thanks for all the wonderful work you`ve been doing!

I buy lengths of velcro and stick the board to the back of the pots using that. If I wanted it as secure as possible then I'd use stand-offs screwed to the box, but I don't think they're necessary unless you're particularly heavy handed with your pedals. Velcro has always worked perfectly for me.

DeleteTo cut the board I've used lots of different ways over the years. Scoring with a Stanley Knife or box cutter and then snapping, Dremel, etc etc, but for me the best and safest way is just to use a junior hack saw. I do it a little on both sides, snap it off, and then smooth down the sides with a bench grinder, but if you don't have a grinder just cut all the way through with the hack saw and it will be neat enough.

Hi all.

ReplyDeleteI have a need. I have a 2 channel amp. I use a pedal board.

I need a stomp box that will let me use channel 2 w/o effects and switch to channel 1 with effects. Is there a non-powered simple build for this. I have built a lot of Marks stuff but am not sure what I need.

jeff

Hi, this post isn't really related to this particular post, but i'm wondering if i could replace vero with cardboard, cause i really don't like to be using it for the possible toxicity. I know it's possible to solder into cardboard, but what i'd like to know if there is some hazard like the cardboard catching fire or something when in use. I also know that it's been used for example with the Paperduino (http://lab.guilhermemartins.net/2009/05/06/paperduino-prints/). Besides the cardboard i'm also thinking of maybe using wood though using cardboard would mean a lot less trouble. Anyways, i'm trying to just find a good, non-toxic substitute for vero, so if someone should have any ideas i'd like to hear them.

ReplyDeleteNow you got me interested. What are the toxins in stripboard?

Delete+m

I'm also interested to hear but personally I'd say the solder fumes are the real hazard here. Even good non toxic solder fumes are still pretty toxic over time compared to heating up copper strips on vero. Interesting topic though and keen to learn more.

DeleteWell, I just heard about this yesterday, and supposedly the bad thing about vero is that after you cut or file it or whatnot, inhaling the debris/dust would be very bad for you. So what I did today is I looked up what this vero that they sell here in Finland cointains and it says it's made of paper and pertinax, which I then googled and found out contains phenol formaldehyde resin, which supposedly (maybe) is the toxic part in it. Not completely sure yet though, and not sure either if that is the stuff they use in all stripboards. Anyways I'm still trying to find this stuff out and am gonna ask the guy I heard about this from if he knows any better or where his information is from.

DeleteAbout the solder fumes, I personally use an active carbon filter ;) while soldering (I do this at kitchen/living room) so myself or no-one else needs to be inhaling that stuff anyways (at least all that much).

Muahhahaa, I cut my Vero with a dremel, so if I suddenly stop posting, I'm probably writhing in a toxic cloud of vero board dust.

DeleteI can understand some peoples concerns, but if I was put off everything that had the potential to be bad for me, I'd be bloody miserable. If you concern in phenolic board then consider epoxy fibre instead:

Deletehttps://www.veroboard.com/

As far as the cardboard goes, you could make these things on literally anything with conductive tracks, so yes there's no reason why it wouldn't work. Personally I think I'd prefer to use the proper stuff which will always be physically more robust, and if I have concerns about dust, use a face mask when cutting and clean up after myself with a hoover. Or think about the alternative material like epoxy.

But to each his own, if you try it let us know how you get on.

I might want to give a epoxy fiber a chance at some point anyway...

DeleteI think you need to eat a whole lot of pertinax on every breakfast before it makes any difference. I smoke ~2 packs a day (and have been doing so for the last 22 years), plus earlier i've worked in environments that are not the best ones for your lungs. It may be just me, but i don't see the risk on this one. Besides, the acids used for etching PCBs are not exactly fruit juices either...

On solder fumes - you'd need to go way higher with the temperature to make lead a gas. 1749 °C to be exact. Same goes for the tin at 2602 °C. So using an iron with ~400 °C temperature won't make those metals hazardous. What the flux agents have in them, i'm not sure. But trust me. You won't get lead poisoning by soldering.

+m

Do you know a place that sells that epoxy board? Because normal "paper"-based Veroboard builds aren´t something that you can give anything like lifetime guarantee to. I´ve seen those boards go totally crumbs in demanding use (from a cold trunk to warm stage daily). They really don´t like condensation and moisture + maybe bit of shake in the back of gig bus eats them quickly compared to PCB.

DeleteI've heard a lot of talk about standard paper based stripboard being unworthy building material compared to factory made PCBs. No. I do not agree with any of you. I just did a little experiment. Threw a couple of stripboard pieces in a jar with water and left it be for 6 hours. No. They don't suck the water in them and no. They didn't crumble or anything else. These pieces are just as solid as they were 6 hours ago.

DeleteI sure would like to see a photo of stripboard that's broken.

+m

Phenolic boards are in plenty of stompboxes from the 60s and 70s which still work perfectly well, and some people will pay thousands of pounds/dollars for, so I'm not too concerned about its longevity. I think the electrolytics will pack in before the board does.

DeleteFunny that I have done the same test. Actually I had a piece of stripboard in water for a couple of days and let it dry and put back to water, but that also seemed almost as hard as it was new after the experiment. There might be different types of "normal" stripboard material too or then that waterglass-test doesn´t equate real-life situations where the moisture might also get frozen time to time plus all the shaking etc.

ReplyDeleteI am thinking about building my first pedal and I don't have a power drill at home, is there any way to cut the traces without a drill, or do I need to borrow one? Thanks in advance

ReplyDeleteHey Wes

DeleteGreeny drills holes so he can clearly see where the cut needs to be and it makes it a little easier but you can do it without one.

I mark all my cuts with a permanent marker and use a appropriately sized drill bit in my fingers to cut them. I just hold it in the hole, give it a couple of quick flicks of the wrist and blammo, nice clean cut.

If this is not an option you can just score a line in the trace with a sharp knife (box knife etc), as long as you are sure it is clearly cut it will work fine too.

There's also special tools just for this job but if I was going to buy one of those I'd buy myself a new power drill while I was at the shops haha

Have fun. Your going to love it!

This comment has been removed by the author.

ReplyDeleteGreat guide! I just don't quite understand the color codes for the condensers. Which ones are the red ones and so on?

ReplyDeletethis might be a stupid question but what are those two blue dots on the upper and lower corner of the layout drawing? thanks!

ReplyDeletesorry if this sounds a bit stupid to ask, but does the direction of the switch matter? I mean by looking at the diagram, is there anything indication to which direction the foot switch should be in (i.e. horizontal, vertical, etc.)? Sorry I'm very new to this and still learning very slowly.

ReplyDeleteHi! I'll try a reply here. The direction matters. You shoul pick the switch and the see the poles as horizontal lines. This way, the horizontal line in the middle (3 poles) is the common. As you can see in the pic nº 17, the input and output jacks goes right there.

DeleteAm I clear? sorry the poor english

Hi Guys, First let me say thank you to the person/people that put these layouts up. I have had 3 successful builds so far and managed to upset my mate with my £12 SHO Compared to his £130 one.....well he is also a drummer.....I am looking to complete this build over the weekend and with been a complete novice I am looking for a touch of advise...

ReplyDeleteWhat if any difference would it make using 1n4001 diodes instead of the 1n914.... I have ordered both.....

Thanks in advance....

Different diodes clip at different forward voltages and thus produce differing harmonic tones or smoothness. You could socket them and try as many as you like. I'm with Greeny though 1n4001s sound killer in pretty much anything

DeleteThanks chumbox.......do I take it that different diodes have different values so they clip the wave form at different points?????

ReplyDeleteAgain thanks all help appreciated as I am a complete novice

How do i know how to wire the led, buttons, jack inputs etc??? that's not in the schematic...

ReplyDeleteThank you =)

First, the layouts are not schematics. Second, have you checked the page on the top menu, called "Offboard"?

Deletehttp://tagboardeffects.blogspot.fi/2012/02/offboard-wiring.html

+m

Thanks for this really helpful guide!

ReplyDeleteA have a question about the cosmetics of the pedal, not about electronic... Is there a proper and timeless method of painting the enclosure? I'm thinking of sintering or anodizing, but these methods are a bit hard-to-do at home...

The guide is great for a newbie.

ReplyDeleteMy main problem in making boards that worked was counting the holes in the veroboard in order to place components and constantly losing or mixing up the hole count and placing them in the wrong place.It can get very confusing.

I got over this by placing a wide piece of masking tape over the "raw" strip board and rubbing it firmly down to be able to see the ghost of the holes.

I then use a fine marker pen to identify the strip cut locations with a square and punch out the corresponding hole in the masking tape before drilling..

I punch out a hole for each end of the resistors and links and draw a straight line between them. For the capacitors I do the same but mark the line with ring or oval to distinguish from resistor lines.

It is just about possible to circle semiconductor pins and mark transistor and diode pins with a letter (C.B.E. D.S.G etc.) Wires are also located with holes punched out.

The result is that I can populate the board accurately and wire connectors to the correct strips even when leaving the board part way completed until days later.

Hi!

ReplyDeleteThe wiring you did on the 3PDT switch here is much cleaner than the one on your Off board wiring page. Can you share with us the exact diagram here?

Thanks!

The switch wiring above does not ground the circuit input during bypass like Marks diagram in the Offboard section. I would recommend sticking to Marks wiring, especially in high gain circuits to minimise potential noise/crosstalk when bypassed. But as for above...

DeleteSwitch lugs

1-4-7

2-5-8

3-6-9

1 = Circuit Input

2 = Jack Input

3 linked to 9

4 = LED Anode

5 linked to 6

6 = Current resistor to V+

7 = Circuit Output

8 = Jack Output

Hi Frank (and Ciraran) Just wanted to say I use Greeny's 3PDT wiring all the time and have had no trouble with the grounding problems people often refer and that is with medium-high gain circuits as well. Just be sure everything else is grounded well in a good quality enclosure and 9/10 times you'll probably be fine. Have fun.

DeleteI still have to buy my components. My question is can I use box type capacitors and bend their leads like you do to those panasonic/phillips caps?

ReplyDeleteHey Renato

DeleteMost standard box caps span 3 spaces as in the vero used in this example (and most veros on this site) except for the 100p which would be a tiny ceramic one. You'll find they fit perfectly on most veros you see on this site. Occasionally you'll some film ones span 4 spaces you'll need to do some bending as Ciaran noted.

Good luck!

Yes you can. Some box caps come with short legs making them difficult to span more than 4 rows without modifying then so just bear that in mind. Good luck

ReplyDeleteThank you so much for the replies. I've been mulling over a parts buy at Tayda's for a startup in pedal building and I think I should proceed with the purchase now. Thanks1

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteIt's really a fantastic information and may creatively response plenty of inquiries some individuals could have any time seeking build-up these kinds of outcomes.

ReplyDeleteguitarscamp.com/best-electric-guitar

what kind of wire do you use/recommend? solid or stranded? fabric or plastic?

ReplyDeletewould be great if you guys could build examples on a traditional prototype Breadboard (5 columns+5columns) so we could learn by changing components instead of soldering them

ReplyDeletei also love Fritzing software that actually convert anything in boht bread to schematic and pcb...

HI, sorry for a stupid question, I am a beginner What is the reason for (Tracing a board before you start, do you make the hole all the way through.

ReplyDeleteTim just uses those from the layout as an indication where the cuts need to go. You can drill straight through if you want, plenty of people do it that way, but I use a simple drill bit on the copper side to cut through the track to make the required break

DeleteI know this is a noob question but can't tell from the pictures...when you create the links in the diagram, is the goal simply to connect the circuit in the top hole to the bottom hole or do you need to try to get solder through every hole to the jumper wire (line of solder spanning all the holes). I'm 90% sure it is the first but all the pictures I've seen of perf boards with the individual copper holes that needed everything soldered. I ordered the stripboard to alleviate some of this soldering but wanted to be sure about how to connect the leads properly.

ReplyDeleteThey sell two kinds of strip board. You should get the one that has tracks so that the current will flow down the track.

DeleteThere's only one kind of stripboard actually. The one that has individual pads is known as perfboard and will not work for the layouts on this site.

DeleteTo answer unknowns question about links, the like is a wire that you run on the top of the boards, i.e. the side without the copper tracks, and does as you first say, connect the row at the top hole to the row with the bottom hole.

How is the board mounted to the enclosure? Does it just rest on the pots, or does all the wiring hold it in place?

ReplyDeleteEveryone has their way, so I can't you specifically what to do. What I do is use a piece of a wood dowl and glue the board to one side and glue the other to the enclosure. You could use double sided tape to stick it to the enclosure or back of the pots too. As long as the board doesn't ground out you should be fine.

DeleteThank you for this site and all the valuable information! I've been wanting to build my own boxes for a while now, and this site has really opened up a world of options for me. Sites like this and the free sharing of information are what makes the internet great!

ReplyDeleteP.S. If anyone has a layout/BOM for the Friedman BE-OD, I'd love to see it ;)

Ive been using this site for a while, i happened to check out the build guide. I noticed that he omitted the 100pf cap, and there is a 1n4001 in its place. Could anyone advise on why? It just happens that im down to last of my stock and have these exact pots, which is crazy bc i never seem to have what i need lol. But if anyone could give me some insite into why the diode is used instead of the pf cap id really appreciate it!

ReplyDeletei've got a newbie question here. Do you place all the components on the vero, and then you solder them, or do you solder each one on the board when placing them?

ReplyDeleteYou know what would be nice? If there's a section of 'best and worst' circuits. Then votes put circuits in categories based solely on whether its a good layout or bad layout. By this I mean layout principles which make a circuit work well, vs which have cross-talk, power and signal in wiring too close together, long parallel runs of wire or other issues which cause parasitic capacitance, etc.

ReplyDeleteBy having a catalog of what is best and worst in circuit design people can more quickly and easily figure out the rules for good design principles. I have scoured the net and have not found the solutions to these questions:

How do you make a circuit fit in as small a space as possible?

How close can certain wires be before issues arise?

Is crossing over other wires a problem, if the wires run perpendicular with one on the underside of the board and one on top?

Pfff, When watching this, it looks so easy...

ReplyDeletehey I just realised that I've been trying to build a pedal placing the components on the vero mirrored since I used to build them on diy pcb. Will soldering them mirrored affect them in any way or will the build still work?

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteHi! I bulit this after a every noob's 1st bulid (the fuzz face), and it's doesn't do the trick.

ReplyDeleteI'm testing the finished strip-board with a breadboard (no bypass switching), it let's trough the sound but it doesn't distorting or modify. And it's a bit noisy.

And I've got the same problem with my 3rd bulit, an EHX Big muff. It lets trough the clean (bit noisy) guitar tone, but does nothing else.

Any idea where I screw them? Maybe I overheated some components?

Forgive my newbieness, but where is the output in the board?

ReplyDeleteThanks Ivlark for a very useful service. I appreciate the imagination and skill required to layout these boards. I have built many boards but I completed my first successful build on this site (mxr noise gate) and would like to offer the following suggestions:

ReplyDelete1. Schematics are a must for troubleshooting. Each component should be referenced with identifier such as R1, C1, U1, etc. This makes troubleshooting and discussion on the forum much easier.

2. Consider flipping the second image of the board that shows cuts and traces so that it is displayed as viewed from the copper side. This reduces possibility of errors and simplifies verification.

Keep up the good work!

This excellent guide will help a lot when I make my first pedal shortly. The one big mystery left is how to connect/solder the pots... I do not have a clue based on this guide. The schematic talks about Vol 1 and 2, but only mentiones Vol 3...

ReplyDeleteNobody else seems to be bothered, so I am probably dumb :)

But.... If anyone can shed some light on this....

The wire to Volume 3 is in the vast majority of cases the output of the circuit. If you look in the notes of the layout you will usually see:

DeleteVolume 1 to ground

Volume 2 to output (stomp switch)

The pot numbering and switch wiring can be found here:

http://tagboardeffects.blogspot.com/2012/02/offboard-wiring.html

Thank you, Ivlark. This really helps. The same goes for "Bite" and " gain" in this example I guess? I still do not understand it well: Bite goes to pin 1 on the pot and then? Pin 2 to output and 3 to ground?

DeleteNot necessarily. The volume pot is acting as a voltage divider that will let all the signal through or dump some of it to ground and so reduce the output volume. Gain pots are usually just acting as variable resistors and so only 2 of the pins need to be connected to anything (although you will often see pins 1 and 2 or pins 2 and 3 linked.

DeleteBasically a variable resistor will move the wiper (pin 2) closer to either pin 1 or pin 3 depending on which way you have rotated. The variable resistor mode is just altering the resistance between two of the pins. Have a read of this to better understand how the potentiometer works:

https://www.electronics-tutorials.ws/resistor/potentiometer.html

I don't know if someone has asked this already, quite a few comments to read through.

ReplyDeleteBut I followed this layout for the Frantone LoTone Classic Fuzz and the pedal is working, but the LED is not functioning. Any recommendations?

Check the polarity of the LED?

ReplyDeleteAt the outset, I wanted to say that I am a complete novice and the question is extremely simple and stupid. In the scheme on the right, there is one 47u element (marked with blue colors). In the picture it is black. What is this? Is this a type of electrolytic capacitor? Thanks for help ;D

ReplyDeleteYes that’s just the colour of capacitor that he used. I have them in all colours so the one shown in the layouts isn’t significant as long as it’s 47u with an appropriate voltage rating

Delete